Total No. of Pages:

Register Number: 7536

Name of the Candidate:

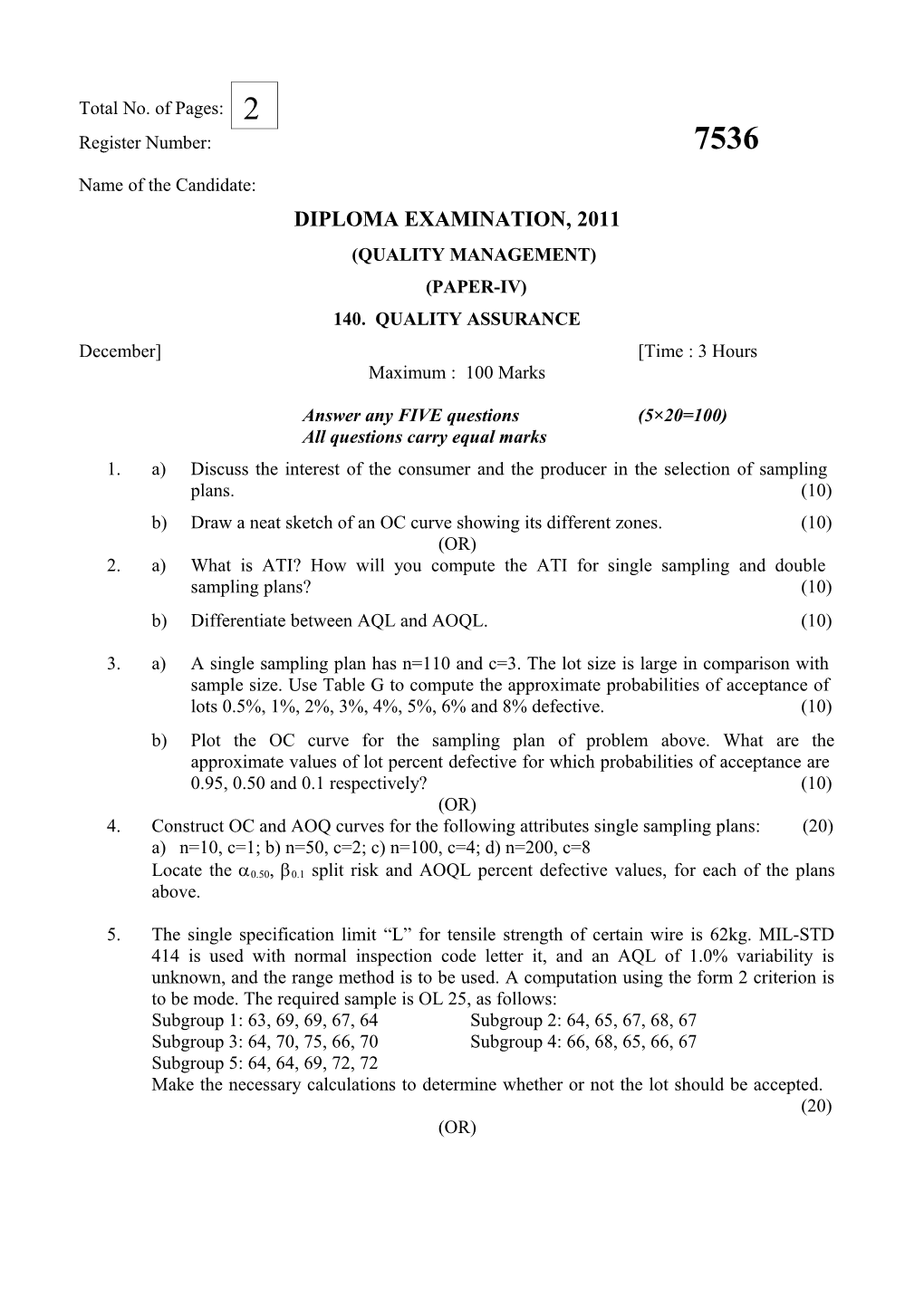

DIPLOMA EXAMINATION, 2011

(QUALITY MANAGEMENT)

(PAPER-IV)

140. QUALITY ASSURANCE

December] [Time : 3 Hours

Maximum : 100 Marks

Answer any FIVE questions(5×20=100)

All questions carry equal marks

- a) Discuss the interest of the consumer and the producer in the selection of sampling plans. (10)

b)Draw a neat sketch of an OC curve showing its different zones. (10)

(OR)

- a) What is ATI? How will you compute the ATI for single sampling and double sampling plans? (10)

b)Differentiate between AQL and AOQL. (10)

- a) A single sampling plan has n=110 and c=3. The lot size is large in comparison with sample size. Use Table G to compute the approximate probabilities of acceptance of lots 0.5%, 1%, 2%, 3%, 4%, 5%, 6% and 8% defective. (10)

b)Plot the OC curve for the sampling plan of problem above. What are theapproximate values of lot percent defective for which probabilities of acceptance are 0.95, 0.50 and 0.1 respectively? (10)

(OR)

- Construct OC and AOQ curves for the following attributes single sampling plans: (20)

a)n=10, c=1; b) n=50, c=2; c) n=100, c=4; d) n=200, c=8

Locate the 0.50, 0.1 split risk and AOQL percent defective values, for each of the plans above.

- The single specification limit “L” for tensile strength of certain wire is 62kg. MIL-STD 414 is used with normal inspection code letter it, and an AQL of 1.0% variability is unknown, and the range method is to be used. A computation using the form 2 criterion is to be mode. The required sample is OL 25, as follows:

Subgroup 1: 63, 69, 69, 67, 64Subgroup 2: 64, 65, 67, 68, 67

Subgroup 3: 64, 70, 75, 66, 70 Subgroup 4: 66, 68, 65, 66, 67

Subgroup 5: 64, 64, 69, 72, 72

Make the necessary calculations to determine whether or not the lot should be accepted. (20)

(OR)

-2-

- A military agency decides to use a variable sampling plan for lots of 200 and for an AQL=4.0. Give two alternative plans that it might use each with two alternative procedures as follows: a) Standard deviation method (form 1)

b)Range method (form 1) (10+10)

- a) Explain the conditions for instituting normal inspection. (10)

b)Explain how to accept or reject a lot using unknown –sigma variables sampling plans. (10)

(OR)

- With an example, explain how variables standard is divided into four sections. (20)

- Write short notes on the following:

a)Basic elements of reliability.

b)Failure pattern for complex products

c)Marginal testing

d)Maintenance and reliability

(OR)

- a) An element has a probability of successful operation over a given period of 60 percent. If four such elements are connected in parallel estimate the improvement factor. (10)

b)Ten transforms were tested for 500 hours each within prescribed operating conditions, and one transformer failed exactly at the end of 500 hars exposure. What is the failure rate? What is the mean life. (10)

------